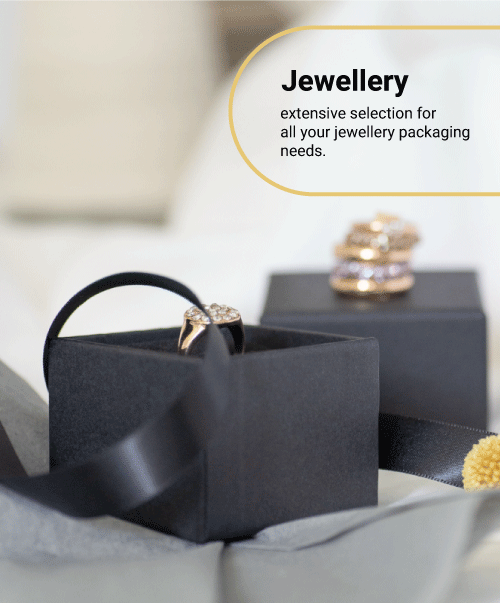

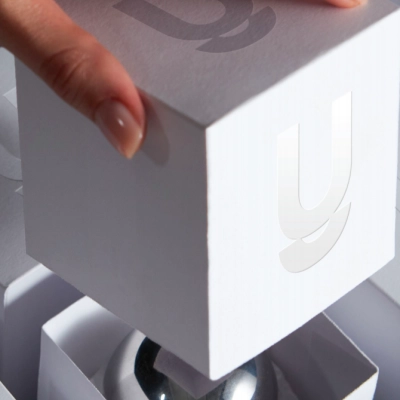

Welcome to Tiny Box Maker! Nestled in Redruth, Cornwall, they're your go-to for sustainable and high-end cardboard presentation boxes, bespoke gift boxes, and corporate gift boxes. With an extensive design range and over 50 combined years of experience in the industry, this team of packaging pros will work hand in hand with you to deliver whatever it is you need - from simple boxes with separate lids to pretty hinged boxes and shoulder boxes, Tiny Box Maker has you covered.

So what different box styles can I choose from?

There's a variety of different box styles that come out of the Tiny Box Maker doors, including:

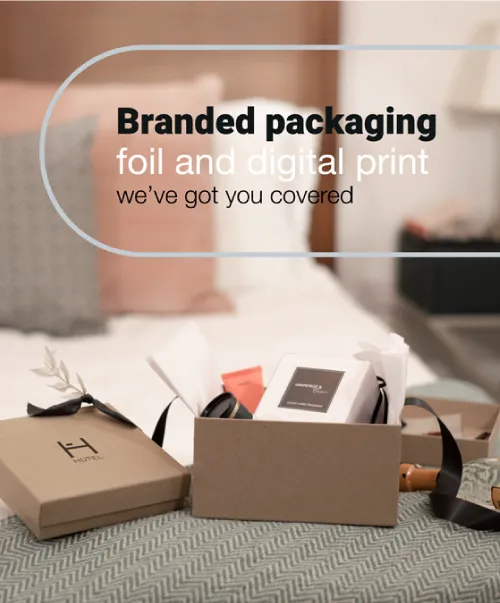

Want to make your mark? Tiny Box Maker offers in-house foil printing to make your branding shine brighter than ever, with digital and litho printing also available. If you're feeling extra fancy, the team can dress up your boxes with stylish sleeves and belly bands to go around the box, with foam or card inserts and luxurious satin lining too that can jazz up the inside.

Box internal options include coloured and printed lining, and choose from box thicknesses ranging from 1250 microns to 3000 microns. (What’s a micron you ask? It’s a tiny, tiny measurement - just one thousandth of a millimetre - find out more about GSM and microns on our blog post here.) There are also several different paper types to choose from - from Wibalin® Natural/Matte (an uncoated, dyed-through paper), to Wibalin® Finelinen (which looks just like finely woven linen) and Wibalin® Flute (with a lovely striped embossing), when it comes to bespoke custom packaging the possibilities are simply endless.

Feeling overwhelmed? Don't worry! The friendly team is just a call or email away. Ring them at +44 (0)1209 314 949 or drop a line at [email protected] to chat about your packaging dreams, budgets and deadlines.

Fancy a peek behind the curtain and see where the box magic happens? Take a look here…

1. Taking your order

First things first, your order is taken by the team - with info like box style, box internals, box thickness, paper type, any branding you’d like, and any extras.

The artwork is then confirmed and signed off by you, the customer, to make sure everything is just right. Once you've given it the green light, the job card is produced. This is a detailed description of the work to be completed, so the team can get to work in making your packaging dreams come true! 2. Crafting the box

2. Crafting the box

When all the details are confirmed, it’s time to kick-start the box-making process.

For this, we need cutting formes - used for cutting and creasing the rigid board, which are ordered alongside the print and blocking dies, if required. What's a blocking die? This is the etched magnesium plate, for short runs, or brass for long runs, used to foil block the boxes (ie 'stamp' the foil onto the surface using heat and pressure).

The board is then cut - this is done by hand if the number of boxes ordered is less than 100, or using a die cutter if it’s more than 100. What's a die cutter? This is used to cut and crease the boards on longer runs, using precise cutting formes.

Next, the paper is cut to fit the box, and then it is mitred for folding around the boxes. For this, a mitre machine is used - this cuts the corners out of the paper so that it can be nicely wrapped over the trays.

The paper is foil blocked, if required, where the box is covered to check the position. A foil blocker is used to, you guessed it, foil block the papers before covering - Tiny Box Maker has a manual foil blocker and a Kluge rotary platen for longer runs.

The board is then stayed up - this means the corners are taped by a machine to turn them from flat card into fabulous, sturdy boxes.

3. Check, and send!

One box is then inspected to make sure everything is all perfect and up to scratch. The boxes are then covered by hand, and are assembled either by simply popping the lids on or taping and assembling if it’s say, a magnetic box.

Any ribbons and inserts are added next, and the boxes are checked again to ensure they're top-notch. The boxes are then carefully packed, with tissue paper to keep them nice and protected. The boxes are then dispatched to you, and Tiny Box Maker gets in touch to make sure you've received them and are happy.

And there you have it! The process of making boxes at Tiny Box Maker - for more on box styles, box internals, thicknesses, and more, check out the Tiny Box Maker website.