Print technologies have come a long way since the early days of printing presses. Today, there are several different techniques available with their own unique features and applications, with foil printing, digital printing, and lithography being three popular methods used in the industry.

Foil printing uses heat, pressure and foil to create different designs and graphics on various materials. Digital printing, on the other hand, uses inkjet or laser printers to produce high-quality prints, and lithography is a traditional printing method that uses plates and ink to transfer images onto paper or other surfaces.

Here, we explore the key differences between these and discuss their advantages and limitations, as well as what’s available here at Tiny Box Company. Let's dive on in...

Foil printing

Up first, foil printing! Also known as foil stamping or foil embossing, this is a technique that involves applying foil to a surface and is commonly used in printing invitations, business cards, and packaging. For this, a print plate is required - this is created by etching your logo or artwork into a metal plate. Foil rolls are made up of thin sheets of metal or synthetic materials and the foil is transferred onto the surface using heat and pressure.

Hot foil is often used in foil printing, and requires the use of a heated die or plate to transfer the foil onto the surface. Foil design options are vast, with various colours and finishes available:

- Metallic foils have a shiny finish and change in gradient colour under changing light conditions.

- Matt foils give a solid fill effect and have a slight shine but the colours stay the same in all conditions.

- Gloss foils give a glossy print effect and have a shine but maintain their colour.

- Satin foils give a shiny print effect with a subtle metallic quality.

- Lustre foils give a soft sheer print effect.

Foil printing adds a luxury finish to your packaging with eye-catching designs and effects, and is suitable for various products including boxes, bags, and ribbon. It is however limited to single-colour designs and requires specific equipment, such as hot foil stamping machines.

When should you use foil printing? Foil printing is a technique that is best suited for specific applications when you want to achieve a luxury finish. Some instances when foil printing can be used include:

- Invitations and stationery: Foil printing can add an elegant touch to wedding invitations, greeting cards, and other stationery items

- Packaging: Foil printing can make a product’s packaging stand out and create a sense of luxury for your brand

- Branding and marketing materials: Foil printing can help enhance the visual impact of business cards, brochures, and other promotional materials

Digital printing

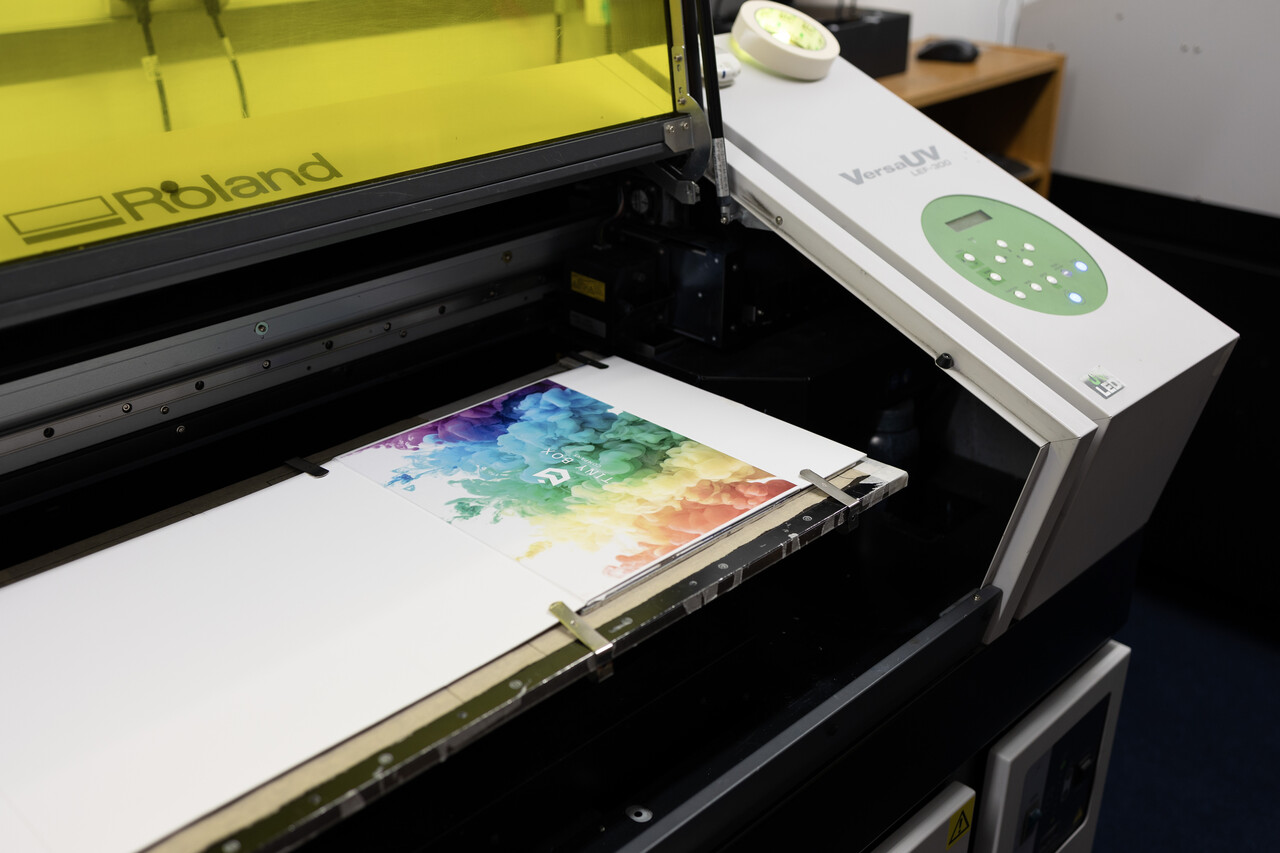

Digital printing, on the other hand, uses inkjet or laser printers to produce high-quality prints. It’s popular due to its versatility and quick turnaround time, making it ideal for small runs, and its opaque ink provides excellent coverage on various materials, including paper, cardboard, and fabric.

Digital printing has a quick turnaround time, allowing for on-demand printing, while still allowing for customisation such as variable data printing. High-quality prints are available with vibrant colours and fine details, and can be used for short print runs, even if you just need a one-off sample for your business.

When should you use digital printing? Digital printing is a versatile technique that is suitable for a wide range of applications:

- On-demand printing: Digital printing allows for quick turnaround times and the ability to print small batch sizes, making it ideal for on-demand printing needs

- Personalised products: Digital printing offers customisation options, such as variable data printing, allowing for personalised products and promotional materials

- Wide format printing: Digital printers can accommodate various paper sizes and widths, making them suitable for large-scale printing projects, such as banners and signage

Lithography

Lithography is a traditional printing method that involves the use of plates and ink to transfer images onto paper or other surfaces. Lithography is known for its high quality and durability, and is often used for large-scale printing projects, such as newspapers, magazines, and posters.

Lithography prints are high quality and durable, with fine details and vibrant colours. It has the ability to reproduce complex images accurately and is suitable for various print sizes. Litho offers consistent and reliable results and is widely used in the printing industry due to its versatility and reliability. Whether it's newspapers, magazines, or posters, lithography continues to be a preferred choice for many printing projects.

When should you use lithography? Lithography has a long history in the printing world and continues to be a preferred choice for large-scale printing projects:

- High print quality: Lithography offers high-quality prints with fine details and vibrant colours, making it ideal for projects that require excellent image reproduction

- Versatility: Lithography can be used to print on various materials, including paper, cardboard, and plastics, making it a versatile option for different applications

- Durability and resistance: Prints produced through lithography are known for their durability and resistance to wear and tear, making them suitable for long-lasting projects

How does each printing technique compare?

When choosing a printing technique, cost considerations, and turnaround time play a crucial role. It’s important to evaluate your budget, project requirements, and timeline when deciding on a printing technique. At Tiny Box Company, we offer both foil and digital printing for off the shelf products and custom packaging - more information can be found here.

What is the most eco-friendly printing option?

The most eco-friendly printing option depends on various factors, such as the materials used, energy consumption, and waste management practices. However, digital printing is often considered more eco-friendly due to its generally lower energy consumption, reduced waste from setup, and ability to print on demand, minimising the use of excess materials.

Can digital printing match the quality of litho?

Digital printing has made significant advancements in recent years and can now match the quality of lithography in many cases. However, lithography still offers good image reproduction and vibrant colours, making it the preferred choice for large-scale projects that require the highest print quality.

Not sure where to start? Don't panic! At Tiny Box Company we offer both foil and digital printing services for our off the shelf products and custom packaging. Book in a free consultation with our skilled team - no need for previous packaging, branding or tech experience, we'll break it down for you to make the process as simple and easy as possible.